In the waste management and recycling industries, safety and efficiency are top priorities. When it comes to bundling solid dry waste, bale strapping has emerged as a safer and more practical option compared to traditional steel or wire straps. Specifically designed to meet the demands of modern waste baling processes, bale strapping offers durability, flexibility, and enhanced safety for both workers and equipment.

One of the most significant benefits of bale strapping is its superior safety features. Steel and wire straps, while strong, pose serious risks during handling and usage. Their sharp edges can cause injuries to workers, and they can snap under tension, leading to potentially hazardous situations. In contrast, bale strapping is made from high-strength polyester or polypropylene materials that are soft to the touch, reducing the risk of cuts and puncture wounds. Furthermore, the flexibility of bale strapping ensures that it can absorb shocks without breaking, offering a safer alternative for bundling heavy or compacted waste materials.

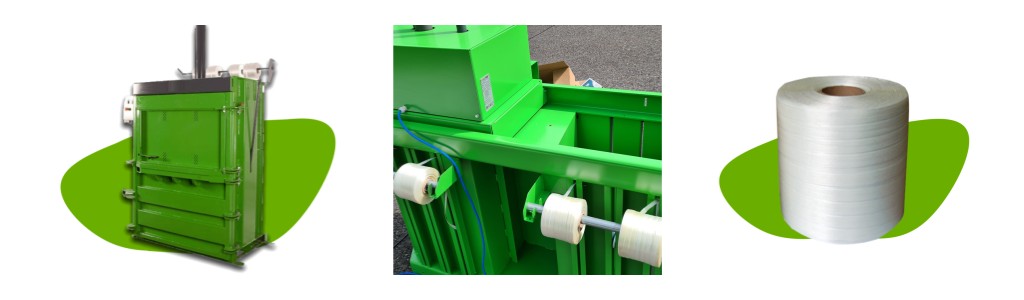

Bale strapping has been specifically engineered to fit the requirements of modern bale presses and compactors. A key feature is its reduced outer coil diameter, which allows it to fit seamlessly into most standard baling machines. This design ensures smooth operation, minimizing the risk of machine jams or downtime. The compatibility of bale strapping with a wide range of baling equipment makes it a versatile and efficient solution for businesses handling large volumes of dry waste.

Despite being lightweight and easy to handle, bale strapping provides exceptional durability and performance. It has a high tensile strength, making it capable of securing heavy bales without stretching or breaking. Additionally, unlike steel straps, bale strapping is resistant to rust and corrosion, ensuring that it maintains its integrity even when exposed to moisture or harsh environmental conditions. This makes it an ideal choice for securing waste materials that will be stored or transported over long distances.

In an era where sustainability is a growing concern, bale strapping offers an eco-friendly alternative to steel and wire straps. Many types of bale strapping are made from recyclable materials, contributing to a circular economy. Additionally, the lighter weight of bale strapping compared to steel reduces transportation costs and carbon emissions, making it a more sustainable option for businesses looking to minimize their environmental footprint.

From a cost perspective, bale strapping is also more economical than steel straps. Its lower material costs, combined with the reduced risk of machine damage and worker injuries, can lead to significant savings over time. Furthermore, the ease of handling and application of bale strapping reduces labor costs and improves overall operational efficiency.

Bale strapping is widely used across various industries, including recycling, waste management, agriculture, and logistics. In recycling plants, it is commonly used to secure bales of paper, cardboard, plastics, and textiles. Waste management facilities rely on bale strapping to bundle dry waste, keeping materials compact and organized for easy transportation and storage. In agriculture, bale strapping is used to bind hay, straw, and other agricultural products, while in logistics, it helps stabilize palletized loads.

Selecting the appropriate bale strapping involves considering factors such as the type of waste being baled, the weight of the bales, and the specifications of the baling machine. For lighter waste materials, a narrower strap may suffice, while heavier bales require a wider and stronger strap for added security. Consulting with a supplier can help businesses determine the best strapping solution to meet their specific needs.

Bale strapping has revolutionized the way solid dry waste is bundled, offering a safer and more efficient alternative to steel and wire straps. With its enhanced safety features, compatibility with modern baling machines, and superior durability, bale strapping is a reliable solution for industries seeking to optimize their waste management processes. Additionally, its eco-friendly and cost-effective nature makes it a valuable investment for businesses striving to achieve both operational efficiency and environmental sustainability. By choosing bale strapping, companies can enhance safety, reduce costs, and contribute to a more sustainable future.